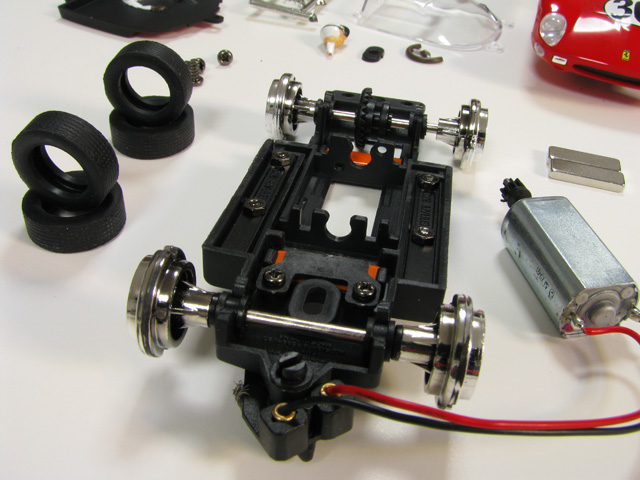

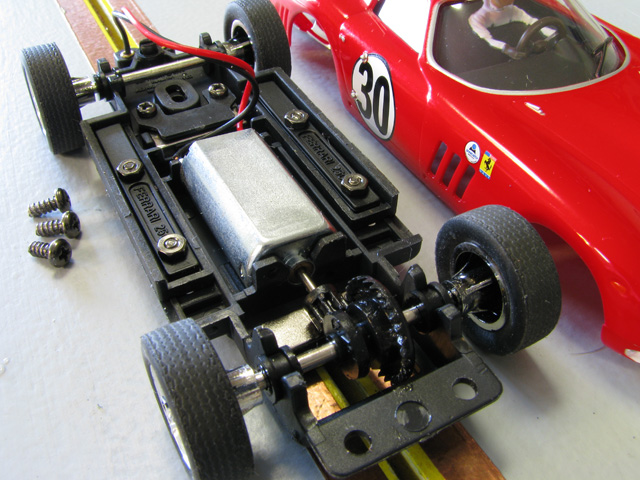

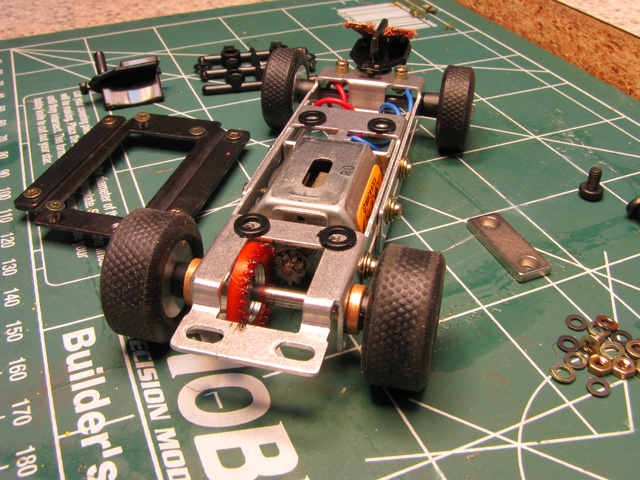

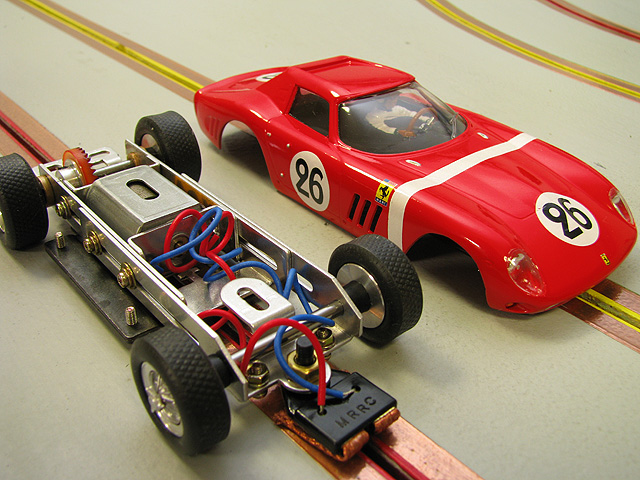

Ferrari 250 GTO/LM Monogram vs MRRC Review By Alan Smith  The new Monogram is a “slot car assembly kit”, which means it goes together quickly and easily. The car body is fully painted and decorated, as is the driver figure and interior tray. All the gears, bushings, spacers, and wheels are assembled and ready to use. The guide flag is wired to the motor, and the chassis is adjusted to the correct length. As the builder, your only job is to snap the wheel sets into the chassis, snap in the motor and the guide flag, and mount the body to the chassis. The only parts that need glue are the interior tray, gas cap, and wheel spinners. For me the most difficult step was determining which of the tiny wheel spinners went on the right side and which on the left. Of course that was an eyesight issue, not a problem with the kit. From opening the box, to the first parade lap, building this kit took ten minutes. For most buyers this extreme ease of assembly is a good thing. For some buyers, like myself, it might leave them feeling vaguely unsatisfied, spending an extra minute or two looking for missing parts that don’t exist.  If the Monogram is barely a kit, the MRRC is the definition of the word kit. The body needs glue, putty, primer, finish paint and lots of sanding before it will look half as good as the Monogram. The all metal chassis is held together by a large bag of nuts, bolts, washers, and screws. Sparing the details, it took me ten days to finish the kit, including lots of time waiting for glue and paint to dry. There were no unusual problems, but the MRRC kit is for experienced builders only. The instruction sheet is thorough, detailing the build with 23 steps and 82 photographs. The final result is not flawless, but more satisfying to me than the easy build Monogram could ever be.  So what is the same about these two kits? The exterior car bodies appear nearly identical to me, the Monogram has more detailed door latches, and the air vents below the fog lights are slightly smaller. The molded in copyright is dated 2008, the body mounting posts are thinner, and positioning pins for the gas cap have been added. The most notable difference is the chrome exhaust system included with the Monogram and not included with the MRRC.   Chassis wise the two kits are night and day. The Monogram uses the well known MRRC Sebring plastic chassis with a slimline motor. Gears, bushings, and wheels are plastic. The metal axles are knurled to hold the wheels. The motor is positioned low in the chassis, below the center line of the crown gear. This requires the use of hypoid gears, resulting in a slightly rough gear mesh. After assembly the front wheels did not spin freely. This was fixed by using a side cutter to remove one of the front wheel spacers.   The MRRC chassis is aluminum and features many precision components. Hardened steel axles, bronze Oilite bearings, and machined aluminum wheels. The chassis can be equipped with either a magnet or a steel “handling kit” that attaches under the chassis, adding weight and lowering the center of gravity. Spacers can be used to adjust the distance between the track and the handling kit. The motor is an inline can with a plastic pinion gear pressed on the shaft.   On the track the two cars are close competitors. Testing was done on a wood track with a magnetic paint surface. The Monogram was tested with the magnets in and the MRRC with the handling kit on and no magnets. Running on 10 volts both cars clocked average lap times in the 5.8 range. For perspective a NSR Mosler tested under the same track conditions averaged lap times of 5.3 seconds. The Monogram accelerates quickly and has good braking. Power slide cornering is predictable and easy to control, but the car becomes jumpy when pushed to the edge. I was impressed with how good the car handles. Not as impressive was the rough gear mesh and resulting loud gear noise. After a few dozen laps the noise level abated somewhat. I later removed the body, put the chassis on blocks, applied toothpaste to the gears, and ran the motor at low speed. Toothpaste is a mild abrasive that accelerates the wear of any high spots on the gears. I also noticed the motor mount was allowing the motor to twist in the chassis a little, and the rear magnet had slipped out of the plastic retaining tabs and was riding on the motor shaft. Using a few strategic drops from a hot glue gun secured the magnet and motor. The noise level dropped down to an acceptable level.   In contrast the MRRC has the feels and sounds like a close tolerance machine tool. It does not accelerate as quickly, and has slightly less breaking effect, but remains cool, calm, and collected right up to the edge. Driving the MRRC fast requires less concentration and would be my choice for an endurance race. The Monogram will hold its own in any Concours d’Elegance, the fit and finish of the model is very good. And of course the MRRC depends entirely on the time and effort you put into the build. The one thing that does stand out, and can be seen in the photographs, is the MRRC has wider wheels and tires that fill out the wheel wells. Side by side the Monogram shows too much gap between the tire and body.   There you have it, two kits miles apart in difficulty but darn close in results. If you have one to build, the MRRC kit is a real challenge that will reward your effort with a jewel of a slot car. The Monogram is affordable and available. It builds quickly into an attractive and fine running car slot car. These are the good old days of slot car racing all over again.  Alan Smith - Asmith Email me about this article |